Notes:

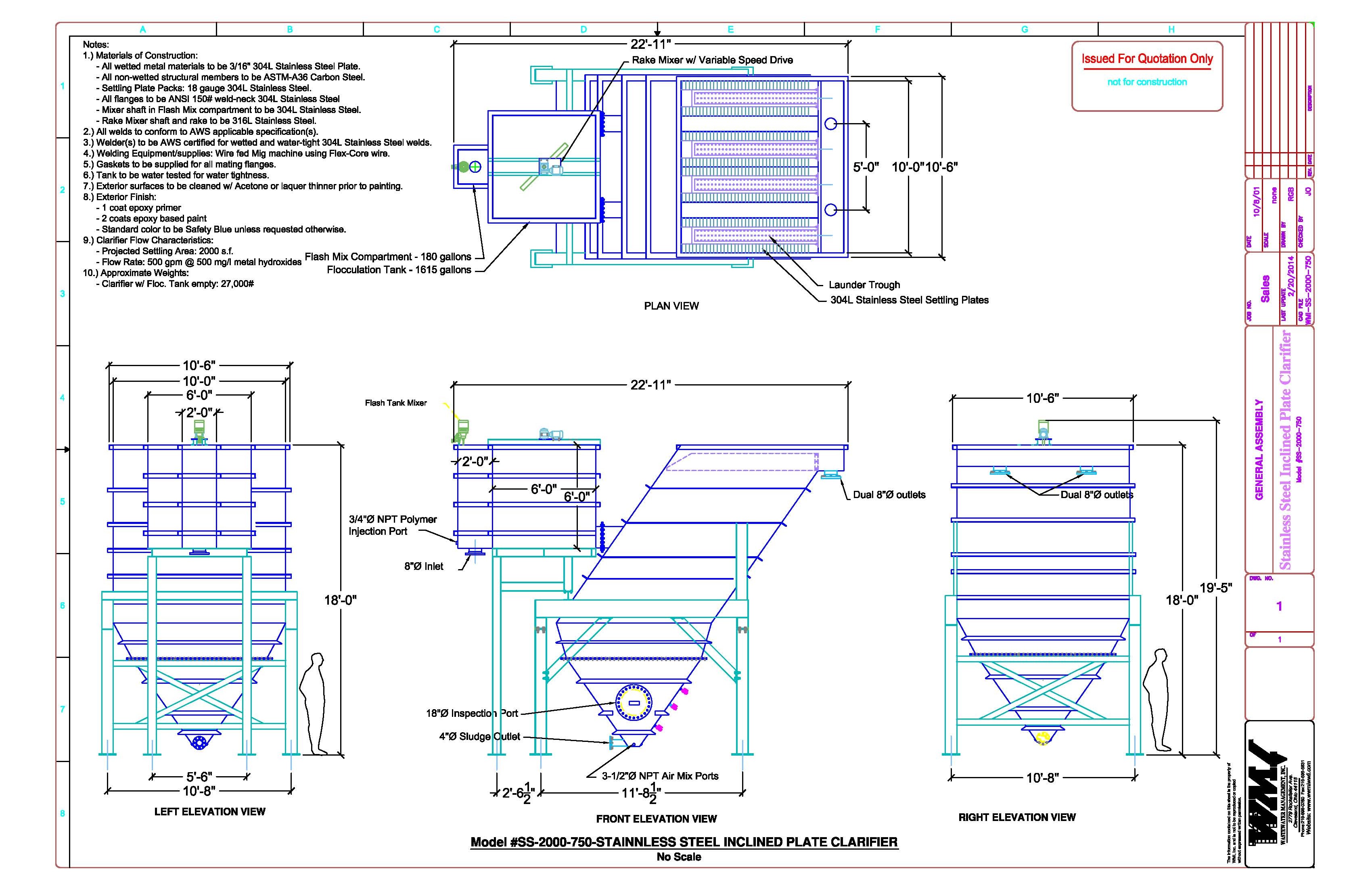

1.) Materials of Construction:

– All wetted metal materials to be 3/16″ 304L Stainless Steel Plate.

– All non-wetted structural members to be ASTM-A36 Carbon Steel.

– Settling Plate Packs: 18 gauge 304L Stainless Steel.

– All flanges to be ANSI 150# weld-neck 304L Stainless Steel

– Mixer shaft in Flash Mix compartment to be 304L Stainless Steel.

– Rake Mixer shaft and rake to be 316L Stainless Steel.

2.) All welds to conform to AWS applicable specification(s).

3.) Welder(s) to be AWS certified for wetted and water-tight 304L Stainless Steel welds.

4.) Welding Equipment/supplies: Wire fed Mig machine using Flex-Core wire.

5.) Gaskets to be supplied for all mating flanges.

6.) Tank to be water tested for water tightness.

7.) Exterior surfaces to be cleaned w/ Acetone or laquer thinner prior to painting.

8.) Exterior Finish:

– 1 coat epoxy primer

– 2 coats epoxy based paint

– Standard color to be Safety Blue unless requested otherwise.

9.) Clarifier Flow Characteristics:

– Projected Settling Area: 950 s.f.

– Flow Rate: 300 gpm @ 500 mg/l metal hydroxides

10.) Approximate Weights:

– Clarifier w/ Floc. Tank empty: 20,000#

– Clarifier w/ Floc. Tank full: 60,000#

WMI-SS-2000-750

Download “WMI-SS-2000-750” WMI-SS-2000-750-Sales.jpg – Downloaded 1687 times – 630.78 KB