Notes:

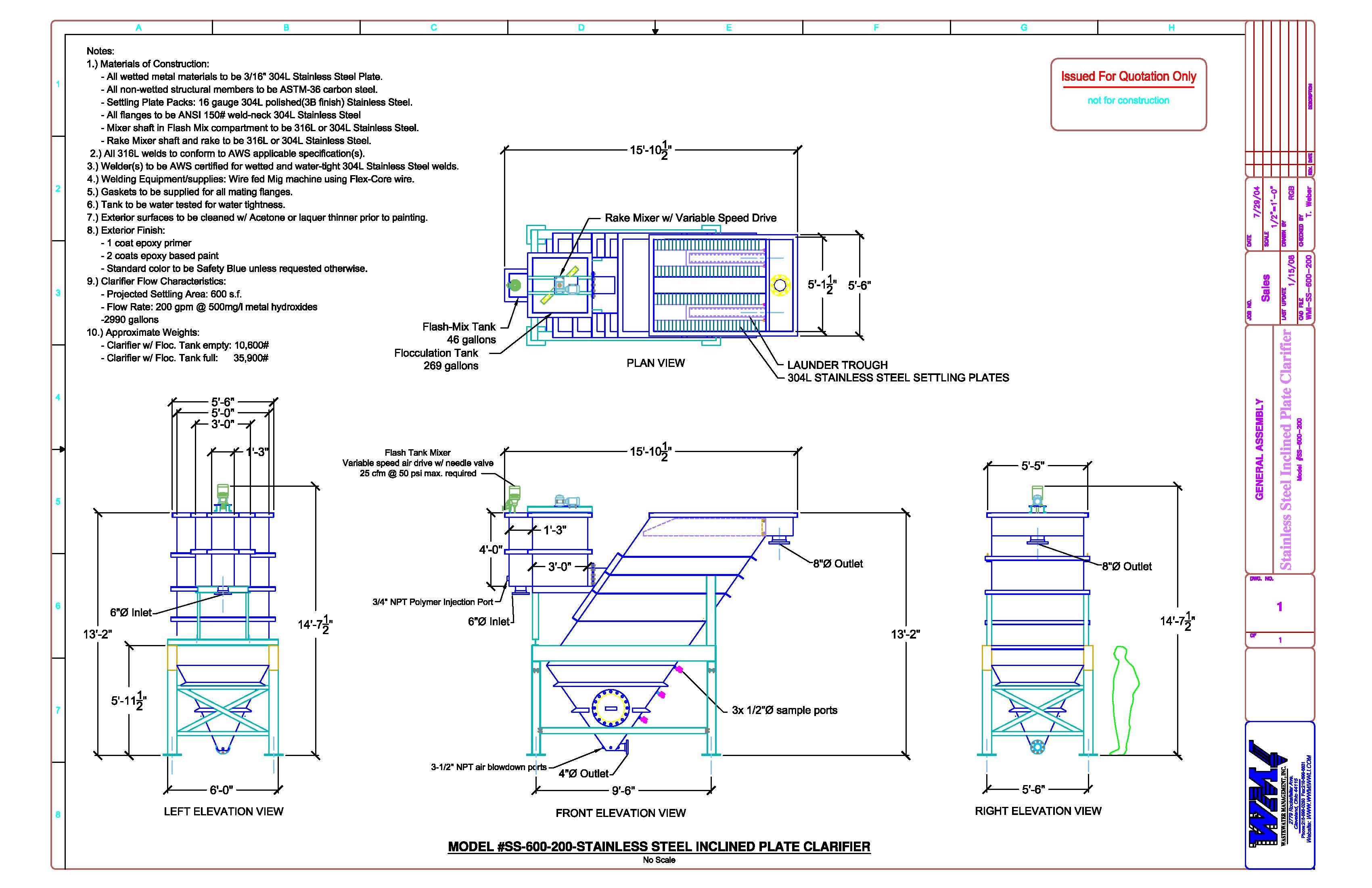

1.) Materials of Construction:

– All wetted metal materials to be 3/16″ 304L Stainless Steel Plate.

– All non-wetted structural members to be ASTM-36 carbon steel.

– Settling Plate Packs: 16 gauge 304L polished(3B finish) Stainless Steel.

– All flanges to be ANSI 150# weld-neck 304L Stainless Steel

– Mixer shaft in Flash Mix compartment to be 316L or 304L Stainless Steel.

– Rake Mixer shaft and rake to be 316L or 304L Stainless Steel.

2.) All 316L welds to conform to AWS applicable specification(s).

3.) Welder(s) to be AWS certified for wetted and water-tight 304L Stainless Steel welds.

4.) Welding Equipment/supplies: Wire fed Mig machine using Flex-Core wire.

5.) Gaskets to be supplied for all mating flanges.

6.) Tank to be water tested for water tightness.

7.) Exterior surfaces to be cleaned w/ Acetone or laquer thinner prior to painting.

8.) Exterior Finish:

– 1 coat epoxy primer

– 2 coats epoxy based paint

– Standard color to be Safety Blue unless requested otherwise.

9.) Clarifier Flow Characteristics:

– Projected Settling Area: 600 s.f.

– Flow Rate: 200 gpm @ 500mg/l metal hydroxides

10.) Approximate Weights:

– Clarifier w/ Floc. Tank empty: 10,600#

WMI-SS-600-200

Download “WMI-SS-600-200” WMI-SS-600-200-Sales.jpg – Downloaded 1983 times – 564.42 KB